Product

- Industrial Centrifugal Fan -- Low Pressure -- High Pressure -- Plug Type -- Plenum fan -- FRP Centrifugal Fan

- Inline Fan - Axial Fan - Centrifugal Fan - Mixed Flow Fan

- Roof & Sidewall Fan -- Roof Fan -- Sidewall Fan

- DWDI AHU Fan

- Tunnel Fan &

Metro Fan - Induced & Kitchen Fume Extractor Fan

- EC Fan

- Other

- Intelligent Control

- Fresh Air and Heating Unit

- INFINAIR Motor

- Customization

High Efficient Inline Vane Axial Fan Impeller Type M - YFIAM

Airflow Range: 4,000~230,000 m³/h (2,353~135,294 CFM)

Total Pressure Range: 30~2,000 Pa (0.12~8.03 in.WG.)

Drive Type: Direct drive

Mounting Types: Base mounted/ Ceiling hung

Applications: General air supply and exhaust/ Explosion-proof air supply and exhaust / Positive pressure air supply/ Smoke removal

For reference only. Please contact our sales rep for detailed performance fan curve. Thank you.

Impeller

- High-efficiency Air Performance

- -- Airfoil blades of optimum air performance.

- -- Vortex hub design.

- -- Optimized design through CFD simulation and experimental verification.

- -- Advanced process used to reduce clearance between the impeller and the cylindrical fan body.

- -- High efficiency and lower operation costs

- Unique Hub-to-Tip Ratio

- -- Hub-to-tip ratio as high as 0.56.

- -- High pressure rise rates to improve airflow capacity.

- -- Reducing airflow loss caused by insufficient pressure.

- -- Particularly suitable for long distance airflow delivery.

- Reliable Structural Design

- -- Advanced casting process to ensure the accuracy and consistency.

- -- Optimized CAE aided design through repeated tests.

- -- Vortex hub of high-strength and greater reliability.

- -- Innovative hub connection that makes operation safer.

- High Balance Quality Grade

- -- The balance quality grade as high as G2.5 (Just G6.3 for general products).

- -- Vibration reduced and reliability improved.

- -- Sound greatly lowered

- Variable Angles Available

- -- 14 impeller sizes in total ranging from 315 to 1400mm.

- -- 8 blade angles in total from 0 to 35 degrees.

- -- 4 speeds in total determined by four poles of 2/4/6/8

- -- Optimized model selection to help reduce upfront investment and operation costs.

Features

- High Efficiency

- -- Airfoil blades of optimum air performance

- -- Vortex hub that smoothes the flow of air and reduces turbulence

- -- Advanced process used to reduce clearance between the impeller and the cylindrical fan body for greater efficiency

- -- Guide vanes mounted behind the impeller.

- Great Reliability

- - Optimized design through the FEA method and experimental verification

- -- Casting process used for core components and high strength achieved

- -- Die forming technique for better accuracy and consistency

- -- Higher balance quality grade and more reliable operation.

- Direct Drive, High Efficiency and No Maintenance

- -- Airflow delivery of higher efficiency

- -- No quick wear parts and low maintenance

- -- Easier and more effective maintenance

- -- Sealed and lubrication-free motor bearing for longer service life

- -- Compact design and space-saving installation.

- Applications

- -- General air supply and exhaust

-

- -- Explosion-proof air supply and exhaust

- -- Positive pressure air supply/ Smoke removal

- -- Two-speed air supply and exhaust

- Convenient and Flexible Installation

- -- Base-mounted: horizontally or vertically.

- -- Ceiling-hung: horizontally or vertically.

- -- Roof mounted: outdoor installation with the Fag-CloudTM weather hood.

- INFI-KOAT Modular FilmTM coating, unfading over time

- -- Pickling, parkerizing and alkaline wash combined to ensure a clean surface.

- -- High-adhesion from being processed in the high temperature furnace.

- -- Resistance to uniform corrosion over large areas and localized pitting corrosion.

Technical

-

Fan Type

The fan shall be the axial flow fan with tubular structure. The drive type shall be direct-drive.

Quality Standards

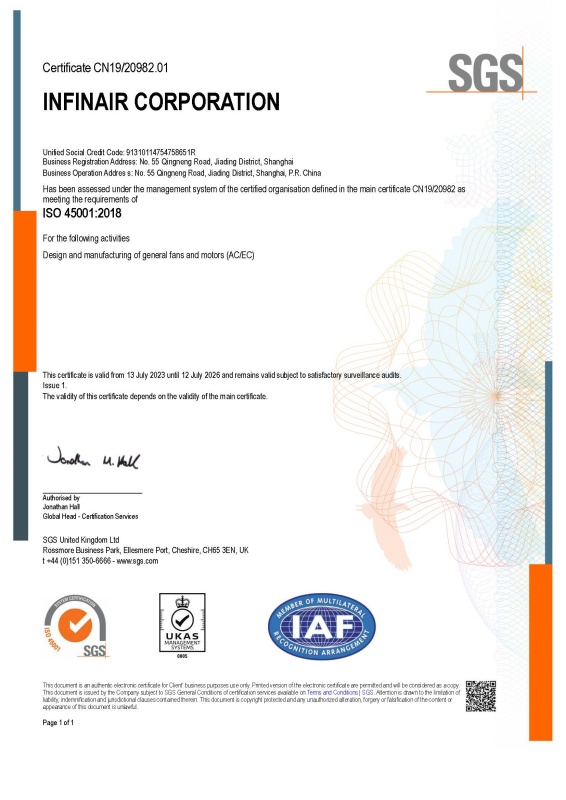

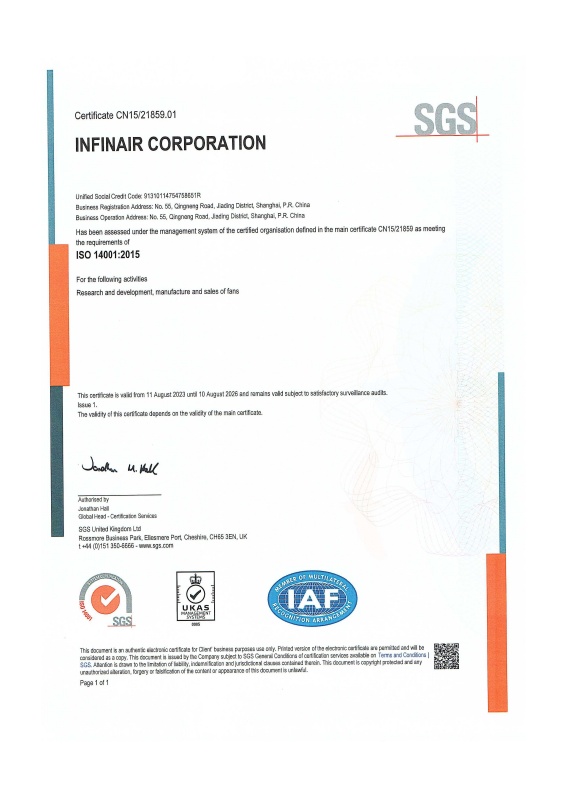

Fan performance shall be tested in accordance with the International Air Movement and Control Association (AMCA) No. 210 and 300 standards. AMCA seal for sound, air performance and FEG shall be tagged on each fan before leaving the factory. The manufacturer shall pass the ISO9001, ISO14001 and ISO45001 system certifications issued by SGS.

Wheel

Wheel shall be variable angle vane axial wheel to meet the needs of the diverse conditions optimization selection. Vane and hub shall be made in cast aluminum which should be adopted by whole molding mould to ensure the strength of the limit of the tolerance 120% speed and improve the structure reliability and the security of the operation. Vane type shall be the wing to own higher aerodynamic efficiency. The fan shall keep stable airflow and low noise at maximum speed. The wheel shall be statically and dynamically balanced to Level G2.5 as per AMCA204 standard. The fan shall be avoided performance degradation caused by slide of operating point effectively.

Fan Housing

Fan housing shall be constructed of continuously welded cold rolled steel panel with epoxy surface, the flange shall be integrated machine shaping.

Structure

The wheel shall be directly connected with the motor. The motor shall adopt B5 installation structure, and its protection grade shall be IP55, while insulation class F and temperature rise B. The motor bearing shall be self-lubricating ball bearing. The power reserve coefficient of the motor shall be per 110% so as to improve the safety in using the motor. Fan cylinder internal should be equipped with guide vane to improve aerodynamic performance and static pressure efficiency, smoother air flow is required, and the blades of the guide vane shall be of 3d curved surface in compliance with flow field characteristics.

Junction box of motor: Since the motor is within the fan, the supplier shall provide junction boxes to lead the wire out of the fan, and correct types of junction boxes shall be selected according to the specific application, such as fire protection type, explosion-proof type and common type.

Coating

Fan surface shall be polished and cleaned up to remove particulates, welding slag, burrs, sharp edge, iron, oil, then epoxy coating [options: colour changes are available], fan surface shall be free of sags, wrinkle, blisters, exposed metal or peeling after coating. It shall be no corrosion and rust at least 10 years in allowable working condition.

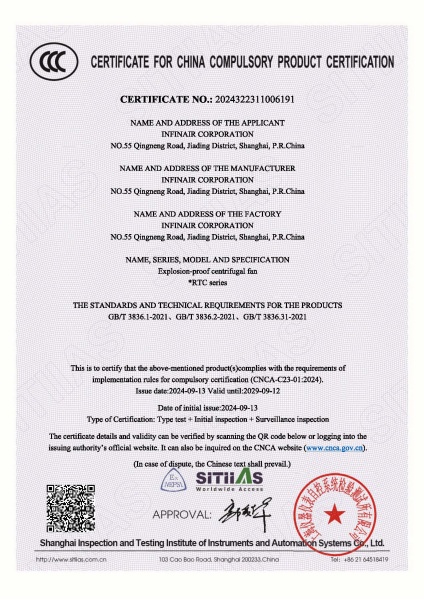

Explosion-proof Structure [Only for explosion-proof type]

The wheel of the explosion-proof fan shall be made in cast aluminum and the motor shall adopt explosion-proof type. The whole fan should own CNEX certification.

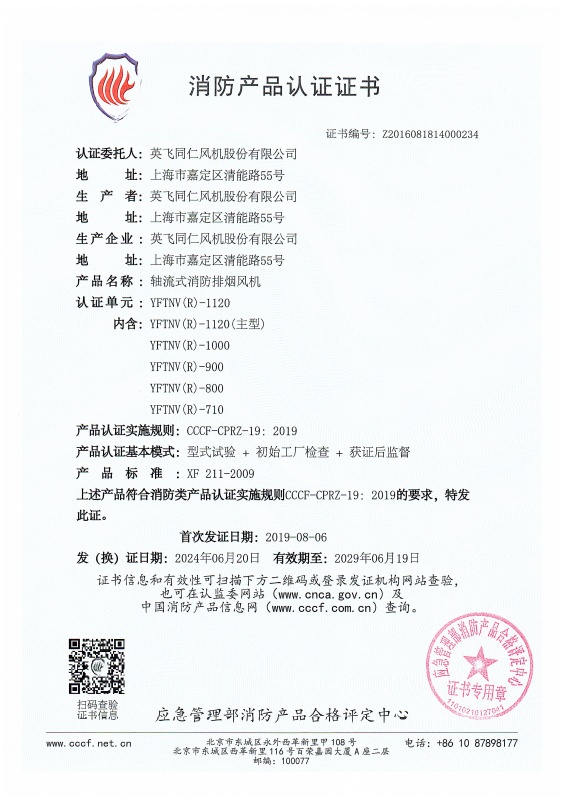

Fire fighting Certification [Only for smoke removal duty]

The fan shall be tested OK in complying with the General Usage Axial Fan technical Specification (China National Standard JB/T 10562-2006). A test report issued by licensed authorities shall be provided. The fan must be tested according to China National Standard XF 211-2009, Fire Fighting Smoke Removal Fan High Temperature Testing Method, running continuously over 30 minutes when the main duct air temperature is 280 degrees centigrade. The high temperature resistance character must be qualified by presenting an official certificate.

Nameplate

Permanently fixed aluminum nameplate shall be fixed on fan body clearly display fan mark, product model and serial number (i.e.: unique ID for each fan), so that the customer can use this number to find out the parts used.

-

Company Video

Welcome to INFINAIR. This video is about our company, including history, products, value, service, technology, production and future. Integrated with R&D, tailor making, manufacturing, and international service ability, INFINAIR provides you complete, high-quality ventilation and industrial process air solution

Company Profile

INFINAIR is an innovative company which provides environmental and intelligent solutions for all aspects of ventilation systems in both private and public sector. They have been INFINAIR’s core values and commitments to our customers over the years.

Trademark: INFINAIR

Established Since: September 2003

Paid up capital: 50,000,000 RMB

Architectural area: 33,000 ㎡

Address: No. 55 Qingneng Road, Waigang Town, Jiading District, Shanghai, P. R. China

Sales & Service Office:

Our sales and after-sale service network promise easy access to customers anywhere in China. They are located in various locations: Shanghai, Beijing, Shenchen, Jilin, Liaoning, Tianjin, Shanxi, Henan, Shaanxi, Shandong, Jiangsu, Anhui, Zhejiang, Fujian, Zhongqing, Sichuan, Hunan, Hubei, Guangdong, Guangxi, Hainan, Guizhou and XinJiang.

Company Vision:

To become the most trusted brand of professional air movement & control solution provider.

Company Mission:

To provide the most reliable and user-friendly air movement & control system.

Product value proposition of INFINAIR: Reliable, Convenient, and Novel.

1. Reliable

At INFINAIR, we prioritize reliability in our products and services. INFINAIR focuses on high-quality system construction, we commit to the constant improvement of product and service reliability:

R&D ability as the basis of product reliability:

At INFINAIR, R&D ability is at the core of our product reliability. Thanks to the extensive experience, INFINAIR has mastered CFD, FEA and CAD technology, fundamentally and significantly improving product reliability. INFINAIR’s air performance lab and noise lab both play a part in forming a solid foundation for product reliability in terms of test scope and precision, as well as in overall investment and construction scale. Our labs are accredited by CNAS, and INFINAIR also boasts the first lab in Mainland China accredited by the AMCA.

Technology and Equipment Reliability Guarantee:

By continually investing in improvements to processing technology and equipment, INFINAIR constantly increases and improves processing capability and precision, assembly methods, production processes, online monitoring, and pre-distribution testing, guaranteeing an ever-increasing level of product reliability.

Third party certification as further proof for reliability:

INFINAIR possesses various third-party qualifications including: Industrial Product Production License, Explosion-Proof Production License, as well as certifications such as ISO 9001, ISO 14001 and OHSAS 18001 qualifications. Most INFINAIR products are compliance-certified by a third party. INFINAIR is the industry leader in terms of both the number of certifications and how long we have held these certifications.

Quality-management system and ongoing reliability:

INFINAIR utilizes an ISO 9001-compliant quality management system, certified by SGS. We constantly carry out 5S and lean production Six Sigma improvement, meticulously establishing a sustainable quality management system.

2. Convenient

INFINAIR features:

-- Complete product configuration and varied impeller forms.

-- Adaptable product selection.

-- Flexible lead time.

-- Quick customization.

-- Prudent product accessory options.

-- By your side service team and quick courier delivery service.

3. Novel

At INFINAIR, we not only pursue products that are like no other, we also pursue innovation. Both of these pursuits aim to give our clients better value.

We offer:

-- Greater aerodynamic performance, energy-saving ability, and noise reduction ability.

-- Simplified, rationally-developed structures.

-- More convenient installation and use.

-- Low maintenance, low total cost of ownership.

-- Adaptable and pragmatic post-sale service.

INFINAIR Laboratory

INFINAIR laboratory is the first AMCA accredited air performance and sound testing laboratory in the mainland of China.

INFINAIR laboratory has successfully obtained the CNAS Laboratory Accreditation Certificate and enlisted in the Chinese National Accredited Laboratory Directory.

Laboratory Accreditation Certificate Issued by CNAS (Chinese National Accreditation Service for Conformity Assessment)

Laboratory Accreditation Certificate Issued by AMCA (Air Movement and Control Association)

All testing procedures at INFINAIR’s air performance and sound testing laboratory are done according to the following standards:

1. All design, fabrication and testing guidelines are in strict accordance with AMCA 210, AMCA 300, ISO 5807, GBT 1236, ISO 13350 and GBT 10178 standards.

2. The INFINAIR laboratory has replaced the simple cardboard shielding method duct test with a new generation of precise-flow nozzle matrix systems.

3. Advanced and sophisticated testing equipment are being used in the laboratory.

4. All equipment used in the laboratory are calibrated and inspected regularly.

5. When comparing the results of same-sample inter-lab tests, the INFINAIR lab test results’ margins of error are within the precision and error requirements specified by relevant international/national standards.

INFINAIR laboratory also has the following test capabilities:

1. perform overspeed test in accordance with JB/T6445 Overspeed test for industrial fan impeller;

2. perform vibration test in accordance with JB/T8689 Fan vibration detection and its limited value and other related standards;

3. perform thrust test for tunnel jet fans in accordance with ISO13350 Industrial fan-Performance testing of jet fans;

4. Designed in accordance with such standards as EN 12101-3 and UL 793, INFINAIR laboratory has built high-temperature furnaces for smoke removal fans for performance tests and as a witness test platform for obtaining TUV, UL and other overseas certifications.

INFINAIR laboratory can perform other tests, such as high and low temperature resistance test, water spray and splash test, physicochemical test, dust test and so on. The laboratory helps ensure precise tests for reliable product quality and accurate technical data.

R&D and Innovation

INFINAIR's Numerical Simulation Technology

INFINAIR owns the industry-leading CFD technology

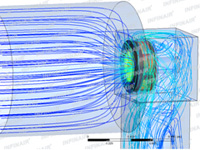

INFINAIR Research Institute masters a set of core CFD technology combining theory with practice owned by INFINAIR itself. Through a large number of repeated engineering applications for many years, now, INFINAIR’s CFD capability is mature and accurate. Besides, in combination with internationally accredited precision laboratories, Our CFD processes have been repeated hundreds of times to allow for comparison between theoretical values and test results, accumulating valuable test data.

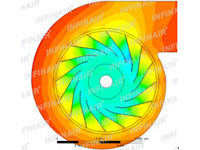

CFD is an important R&D capability of INFINAIR’s Research Institute;; it is featured of high calculated result reliability and fast calculation process. By means of the all-series product utility module system, it can reduce the module development cost of new product at the same time of offering fast customization to customer, and ensure economy while realizing customization.

Successful cases of INFINAIR CFD technology:

1. INFINAIR product generally adopts CFD for systematic development and optimized design, and this is just why INFINAIR is capable of supplying more energy-saving and more efficient products with lower noise. Please see following picture of simulated aerodynamic performance process of INFINAIR complete mixed flow fan, a certain new box-type fan of INFINAIR and a certain centrifugal fan of INFINAIR.

CFD flow field pressure and rate of INFINAIR patented complete mixed flow fan (process illustration)

CFD flow field trace of a certain new box-type centrifugal fan of INFINAIR (process illustration)

CFD analysis for inducing fan of garage (process illustration)

2. With respect to garage ventilation system optimization, INFINAIR has successfully developed a new, complete series centrifugal inducing fan with high static pressure as wehll as far projection distance, and guide the ventilation system layout of underground garage of customer. The following is the flow field layout simulation of an underground garage.

INFINAIR has mature FEA technical capability

1.In the practice process of FEA technology for many years, INFINAIR has accumulated a large number of data and experience which are suitable for actual physical property of common materials in China market.

2.INFINAIR Research Institute fully calculates and repeatedly adjusts the material type, material thickness, structural form and processing way in design stage to ensure that the parts can resist various pressures in operation, ensure that the fan can operate reliably for a long time, and ensure that the product cost is reasonable.

3.The final product scheme goes through the reliability verification of INFINAIR laboratory, conducts failure analysis and life extension analysis for products suffered aging test, reaches a definite conclusion, and thus reasonably saves equipment investment while improving product reliability.

CFD flow field pressure cloud of a certain centrifugal fan of INFINAIR (process illustration)

——Numerical simulation technology CAE

1.Numerical simulation is a kind of application of Computer Aided Engineering (CAE), mainly includes two core technologies of CFD and FEA.

2.CFD is short for Computational Fluid Dynamics. CFD simulate-calculates the product performance inside computer, provides guidance for aerodynamic model design (optimize the number of blades, angles and widths) and noise prediction of fan, especially impeller, and thus helps the designer basically predict the final aerodynamic performance without producing so many prototypes, consequently realizes quick customized design or systemic optimization.

3.As a “virtual laboratory”, CFD can realize fast iteration, save cost and reduce R&D period, is a strong tool for effective and reliable fan R&D and non-standard customization, and will provide accurate scheme for optimization of ventilation system.

Process illustration of FEA stress distribution for customized centrifugal fan impeller made by INFINAIR

Successful cases of INFINAIR FEA technology:

1.The following is process illustration for a customized fan analyzed by INFINAIR Research Institute . According to the system natural vibration characteristics of the customer, INFINAIR Research Institute makes vibration mode analysis for the overall customized fan, achieves structural optimization, avoids resonating with system, and ensures that the fan can operate reliably for a long time.

Modal analysis for fan frame made by INFINAIR Research Institute through FEA

2.In order to analyze the bearing and deformation of motor platform in operating process, INFINAIR Research Institute conducts modal analysis based on FEA technology.

R&D and Innovation: R&D team

INFINAIR Research Institute focuses on “product life cycle” and is fully responsible for management of all products. The responsibilities are as follows:

1.Fundamental research of hydromechanics;

2.Market research of ventilation, gas heating, motor, air purification and automatic control of ventilation system;

3.Product planning, R&D and manufacturing;

4.Customization;

5.Market launch and promotion, maintenance and update/obsolescence;

6.Product experiment and test, product certification;

7.Order processing and technical support.

As a new high-tech enterprise in Shanghai, INFINAIR Research Institute has an excellent technical talent team combing elder, middle-aged and young people and an effective talent cultivating mechanism. Immersing in Youth Culture of Ready to learn, Hard-working, Enterprising, Forward-looking, Innovative, Pioneering for a long time, INFINAIR R&D team has cultivated innovative spirit which has become source for core competitiveness of company.

INFINAIR Research Institute always takes Reliable, Convenient, Novel as the basic concept of product R&D and design. Under the guidance of the spirit and concept, the institute has reached innumerable great achievements, obtained more than 40 patent certificates and won many honors, it has launched many products for the first time in industry, what is more important is that INFINAIR Research Institute takes “at customers’ side” and resolving practical product issues for customer as an important work habit, and thus creates valuable and satisfactory experience, gains full trust of customer. INFINAIR Research Institute will never stop innovating.

Production Capacity

Advanced Technology and Equipment Ensure Product Reliability--Much to expect from just having excellent design and a precise detail-oriented drawing? In fact, there is still a long way to go before finalizing a reliable product that comes only from high processing precision and advanced technology.

-- INFINAIR has put to use a large number of high-precision CNC processing machines. Besides, INFINAIR has produced lots of special-purpose equipment and core molds through its independent R&D efforts.

--Also, R&D staff and production workers at INFINIAR are mobilized to promote technological improvements through concerted efforts. By analyzing onsite issues and sharing the actions for improvement, product reliability has been continuously enhanced with the help of wisdom of frontline workers.

Reliability Certified by Quality Control Systems

--INFINAIR has been awarded triple certification in ISO9001, ISO14001 and OHSAS18001 by SGS, a world famous certification agency.

--INFINAIR performs tests on key points at all stages of production and products must be rigorously tested before leaving the factory to ensure reliability. A case in point: INFINAIR made huge investments in building a vibration test bench on the production line and importing dedicated test equipment from Germany for greater accuracy. This bench covers 180 square meters with its foundation reaching 20 meters underground.

--Furthermore, INFINAIR works with consulting companies to launch 5S programs and take the Six Sigma approach to the continuous improvement of products. In this way, abilities of staff can be improved and a sustainable quality management system built.

The TÜV SÜD Certificate

AMCA accredited lab

AMCA membership certificate

Numerous Product Patents

CE Certification

CNAS lab accreditation

ATEX Certification

ISO 9001 quality management system

OHSAS 18001, Occupational Health and Safety Assessment Series

ISO 14001 environmental management system

Explosion-Proof Certification

Fire Fighting Certification

Case Study

This video is about a signature airport job of INFINAIR ventilation. We participated and competed the bidding for this ventilation project - Xinzheng Airport in 2014.

With the lack of fossil fuel and aggravation of pollution, nuclear power is the unique new power can be Large-scale applied with great prospect.

The Dongfeng Yueda KIA is an joint-venture of Dongfeng Motor Corporation、Jiangsu Yueda Investment Co. Ltd and Korean KIA Automatic Vehicle. Ltd, partly occupying respectively 25%、25%、50% of the company.